AI-Powered Plasma Technology for Enhanced Fabric Performance – Fast, Eco-Friendly, and Waste-Free.

Efficient,

Sustainable

Textile Treatment

for the Modern World

AI-Powered Plasma Technology for Enhanced Fabric Performance – Fast, Eco-Friendly, and Waste-Free.

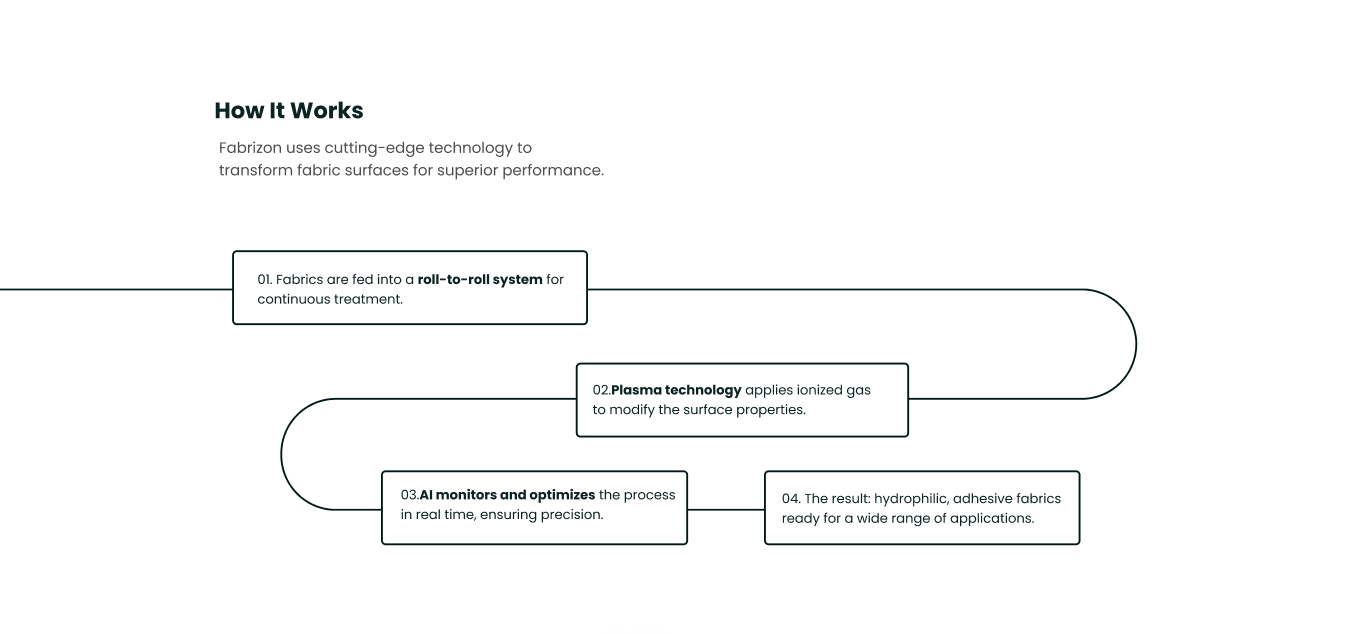

How It Works

Fabrizon uses cutting-edge technology to transform fabric surfaces for superior performance.

01. Fabrics are fed into a roll-to-roll system for continuous treatment.

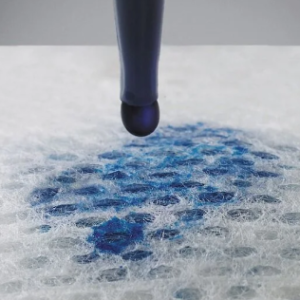

02. Plasma technology applies ionized gas to modify the surface properties.

03. AI monitors and optimizes the process in real time, ensuring precision.

04. The result: hydrophilic, adhesive fabrics ready for a wide range of applications.

- Problem

- Our Solution

Outdated and Harmful Fabric Treatment

Traditional textile methods waste resources, pollute the environment, and fail to meet the industry's growing demand for sustainability. Water-intensive chemical processes release hazardous pollutants, increase costs, and struggle to maintain efficiency in modern production lines. It’s time for a smarter, cleaner solution.

Smarter, Cleaner Textile Treatment

Fabrizon's advanced non-thermal atmospheric pressure plasma (APPT) technology revolutionizes fabric treatment. Our AI-powered system ensures consistent, high-quality results while reducing waste and cutting production time. With roll-to-roll processing, we offer a fast, scalable, and eco-friendly alternative to traditional methods—completely water-free and chemical-free.

- Problem

- Our Solution

Outdated and Harmful Fabric Treatment

Traditional textile methods waste resources, pollute the environment, and fail to meet the industry's growing demand for sustainability. Water-intensive chemical processes release hazardous pollutants, increase costs, and struggle to maintain efficiency in modern production lines. It’s time for a smarter, cleaner solution.

Smarter, Cleaner Textile Treatment

Fabrizon's advanced non-thermal atmospheric pressure plasma (APPT) technology revolutionizes fabric treatment. Our AI-powered system ensures consistent, high-quality results while reducing waste and cutting production time. With roll-to-roll processing, we offer a fast, scalable, and eco-friendly alternative to traditional methods—completely water-free and chemical-free.

Where Fabrizon Technology Makes an Impact

Medical Supplies: Enhanced PPE, hospital linens, catheters, and surgical devices with hydrophilic and antimicrobial properties.

Sportswear: Improved moisture-wicking, breathability, and comfort for athletic apparel.

Automotive: Durable and water-resistant interior textiles.

Agriculture: Protective covers with superior durability and water absorption.

Cleaning Products: More efficient wipes, mops, and other cleaning fabrics.

Why Fabrizon Stands Out

Fabrizon combines cutting-edge plasma technology with AI automation to redefine textile treatment:

Zero Waste

A clean, efficient process with no harmful byproducts.

Delicate Fabric Ready

Non-thermal treatment preserves heat-sensitive materials.

Real-Time Precision

AI ensures flawless quality control and process optimization.

Faster Production

Roll-to-roll processing increases speed and output.

Eco-Friendly

Fabrizon combines cutting-edge plasma technology with AI automation to redefine textile treatment:

Why Fabrizon Stands Out

Fabrizon combines cutting-edge plasma technology with AI automation to redefine textile treatment:

Zero Waste

A clean, efficient process with no harmful byproducts.

Real-Time Precision

AI ensures flawless quality control and process optimization.

Eco-Friendly

Fabrizon combines cutting-edge plasma technology with AI automation to redefine textile treatment:

Delicate Fabric Ready

Non-thermal treatment preserves heat-sensitive materials.

Faster Production

Roll-to-roll processing increases speed and output.