HomeProduct

Fabrizon Automated Fabric Inspection & Plasma Treatment System

Unlock the Future of Textile Excellence

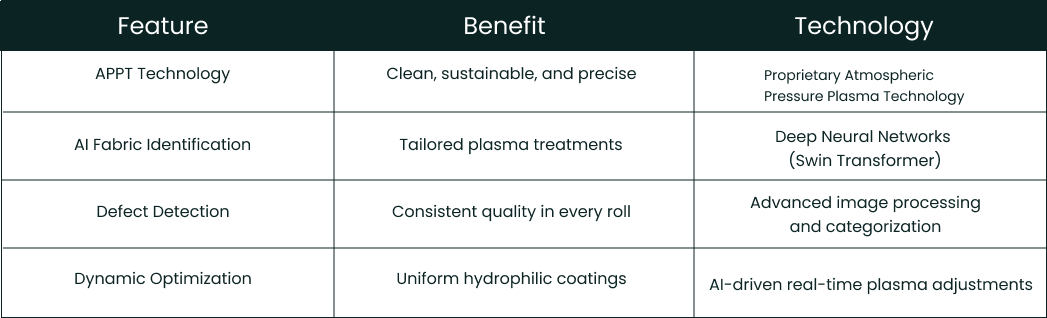

At the heart of Fabrizon’s innovation is the novel application of Atmospheric Pressure Plasma Technology (APPT), integrated with advanced technologies like AI and image processing. This combination enables sustainable, precise, and highly efficient surface modifications in textile processing, offering unmatched quality and eco-friendliness.

How Fabrizon Transforms Your Textile Operations

1. Harnessing APPT for Hydrophilic Coating

- Uses Atmospheric Pressure Plasma Technology to enhance fabric surfaces.

- Optimizes hydrophilic properties for superior water absorption.

- Operates in a clean, chemical-free, and energy-efficient manner.

2. Fabric Type Identification

- AI-powered Deep Neural Networks (DNNs) classify fabrics with precision.

- Tailored plasma treatments ensure optimal results for diverse textile types.

3. Real-Time Defect Detection

- Advanced image processing detects burns, discoloration, and surface inconsistencies.

- Guarantees flawless quality control through continuous inspection.

4. Plasma Treatment Optimization

- Dynamic adjustments powered by AI optimize plasma parameters in real time.

- Ensures uniform and consistent hydrophilic coatings across all surfaces.

Why Fabrizon Stands Out

Fabrizon combines cutting-edge plasma technology with AI automation to redefine textile treatment:

Identify Fabric

AI models classify fabrics for optimal APPT settings.

Apply Plasma Treatment

APPT modifies surfaces for hydrophilic properties.

Inspect Surface

High-resolution cameras and advanced algorithms detect defects.

Dynamic Adjustments

Sensors monitor results and AI fine-tunes plasma parameters.

Why Fabrizon Stands Out

Fabrizon combines cutting-edge plasma technology with AI automation to redefine textile treatment:

Identify Fabric

AI models classify fabrics for optimal APPT settings.

Apply Plasma Treatment

APPT modifies surfaces for hydrophilic properties.

Inspect Surface

High-resolution cameras and advanced algorithms detect defects.

Dynamic Adjustments

Sensors monitor results and AI fine-tunes plasma parameters.

The Power of Advanced Plasma Technology

What is Atmospheric Pressure Plasma Technology?

APPT is an advanced method of surface treatment using plasma under atmospheric conditions. Unlike traditional methods, it eliminates the need for harsh chemicals and high-pressure systems.

- Sustainability: Zero chemical waste and low energy consumption.

- Precision: Customizable plasma settings for every fabric type.

- Efficiency: Speeds up production cycles without compromising quality.

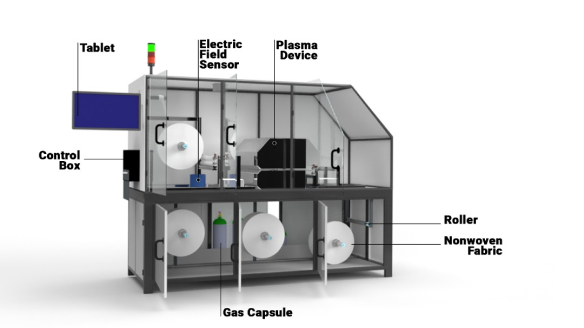

- Hardware

- Software

- APPT Plasma Machines: Advanced systems with adjustable parameters for precise hydrophilic coating.

- High-resolution industrial cameras for detailed imaging.

- NVIDIA GPUs for fast AI processing.

- Surface charge sensors for hydrophilicity monitoring.

- AI algorithms for fabric type classification and defect detection.

- Plasma control systems integrated into an intuitive Node-RED interface.

- Built with Python for seamless AI and image processing operations.

The Fabrizon Advantage: Sustainability, Precision, and Efficiency

- Sustainable Technology: Powered by APPT, our process is eco-friendly with zero chemical waste.

- High Efficiency: Faster production cycles with optimized plasma treatment.

- Unmatched Precision: Over 98% accuracy in fabric classification and defect detection.

Scalable Design: Adaptable to diverse textile types and advanced applications like antimicrobial coatings.

Industries We Serve

- PPE Manufacturing

- Medical Devices

- Sportswear

- Cleaning Products

- Additional Industries: Our technology is versatile, serving a wide range of sectors with tailored solutions to meet diverse needs.

Ready to Transform Your Textile Processing?

Experience the power of Atmospheric Pressure Plasma Technology with Fabrizon.

Revolutionize your operations for better quality, efficiency, and sustainability.